PRODUCTS

Brand Story

CENTER MASTER™

CENTER MASTER™ is an innovative device that dramatically improves the quality of assembly parts by compensating for (positional and/or angular) errors that occurs when assembling various precision parts.

Applicable parts(example)

Automobile components assembly

-

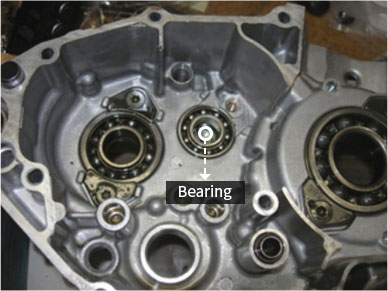

ENGINE - GEAR

- BEARING

- OIL SEAL

- STEEL BALL

- BUSH

- BOLT

- CAP

- PLUG

-

TRANSMISSION - GEAR

- BEARING

- DOWEL PIN

- OIL SEAL

- BUSH

-

DIFFERENTIAL - PULLEY

- BEARING

- BUSH

- PUMP

-

SUSPENSION - BUSH

- RING

- BEARING

- OIL SEAL

- PIN

- SHAFT

-

Electronic components assembly: CD player, HDD, etc.

-

Motor components assembly: shaft, rotor, bush, etc.

-

Air-conditioner components assembly: pins, pistons, etc.

Assembly defects and troubles in the press-fitting process (example) Solved by using CENTER MASTER™

-

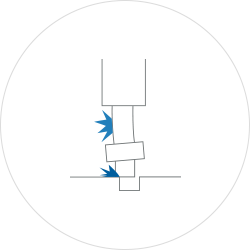

Scratch -

Wedging -

Tearing out -

누유 -

Oil leakages -

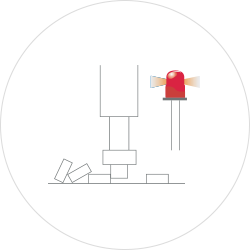

Run-out defect

(vibration, noise) -

Mechanical damage -

Operation stoppage

Improvement example of assembly defects using CENTER MASTER™

Connecting Rod + Copper Bush

Damage/scratches of copper bush

Transmission Case + Bearing

Bearing damage(life), vibration, noise

Front Suspension + Rubber Bush

Rubber bush damage/broken, overload due to misalignment

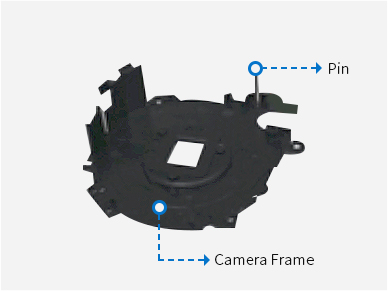

Camera Frame(Plastic) + Pin(SUS)

Scratch, vertical angle error

HDD Spindle + FD Bearing

Vibration

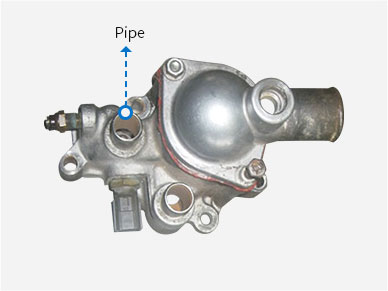

Engine Water Pump + Pipe

Looseness, oil leakage

Bearing Ass’y Caulking

Vibration, eccentric caulking

Spline·Serration assembly/measurement

Misalignment

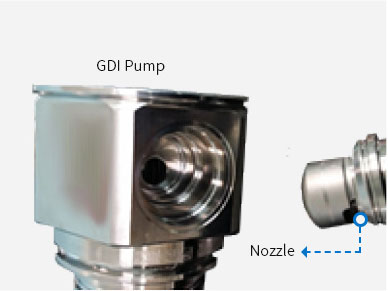

GDI Pump + Nozzle

Looseness, oil leakage

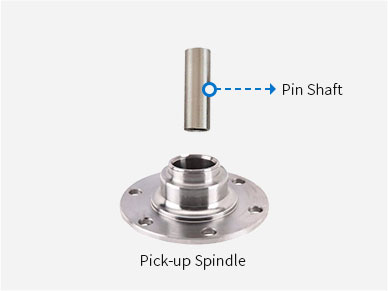

Pick-up Spindle + Pin Shaft

Vibration

Arm Link + Rubber Bush

Rubber bush damage/broken, overload due to misalignment

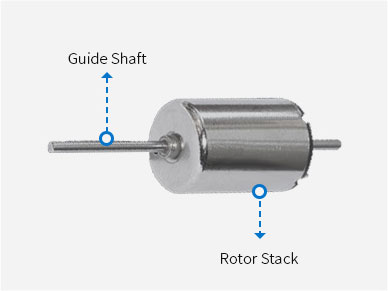

Rotor Stack + Guide Shaft

Scratch, vertical angle errorCENTER MASTER™ installation examples

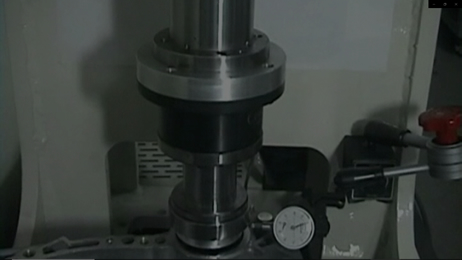

S-Series with hand press

Center compensation with press force measurement

BS-Series with hydraulic press

Center compensation for 12 presses' simultaneous assembly

B-Series with servo press

Center compensation

S-Series with pneumatic press, displacement sensor and indicator

Center compensation with press force measurementSuccessful case of using CENTER MASTER™

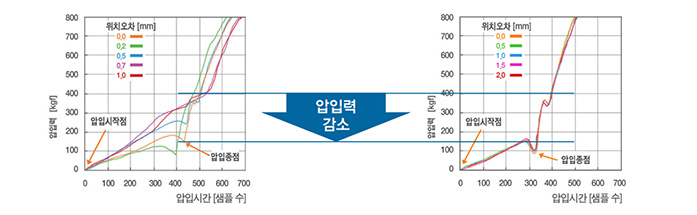

Assembly of transmission case and oil seal

-

< Experiment result graph >

-

Without CENTER MASTER

-

With CENTER MASTER

-

Without CENTER MASTER

- The maximum insertion load is not uniform in proportion to the positional error.

- Quality is not uniform because the insertion load is not uniform.

-

With CENTER MASTER

- The stable maximum pressing load by positional error compensation reduces the defect rate and greatly improves the assembly quality.

-

-

< Experiment video >

Effects of CENTER MASTER™

-

- Significantly reduced assembly failure

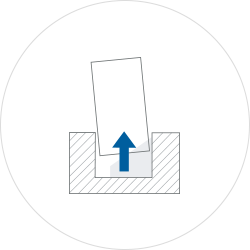

- Compensates for misalignment to significantly reduce assembly failure in insertion or press-fitting

-

- Save of lead time and cost effectiveness

- The amount of time required for a production line -the processing time- is decreased since the precise positioning is not needed and noise and vibration are considerably reduced. And peripheral devices are simplified, so facility investment cost and facility maintenance and repair work are significantly reduced.

-

- Uniform press-fit quality

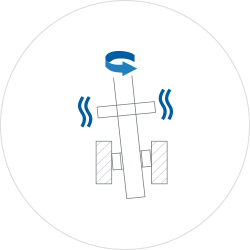

- Uniformly reduced insertion force dispersion by center compensation, drastically decreases defects, and considerably reduces noise and vibration.

-

- Enhanced operation rate

- Reduced errors result in increased operation rate.

-

- Increased binding force between parts

- The binding force between parts increases, because the surface contact density is increased by center compensation.

-

- Longer life cycle of the assembler

- Reduces payload to the assembler to prolong its life cycle and to prevent oil leak and rod distorsion.

CENTER MASTER™ Standard model LINE UP

| Series Function |

A | LA | LT | S | SS | B | BF | BS | BFS | BH | BFH | T | TS | TH | ||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

|

|

|

|

|

|

|

|

|

|||||||

Basic |

Positional error correction | |||||||||||||||

| Angular error correction (only for non-forced assembly) |

||||||||||||||||

| Torsional error correction | ||||||||||||||||

| Rotation prevention (rotational force transmission) |

||||||||||||||||

| Press force measurement (loadcell embedded) |

||||||||||||||||

| Lock-up of error correction during part transfer | Positional | |||||||||||||||

| Torsional | ||||||||||||||||

| Enforced rated press force | ||||||||||||||||

| Shape of machine side plate | Flange | |||||||||||||||

| Flangeless | ||||||||||||||||

| Horizontal direction assembly | ||||||||||||||||

Optional |

Addition of dowel pin hole | |||||||||||||||

| Change of center hole size | ||||||||||||||||

Main customers

Sales Records_Korea

-

2000

Hanon Systems(CENTER MASTER™), LG Display Research Institute, etc.

-

2001 ~ 2010

Hyundai Motors(Oil seal assembly line remodeling, press machine, 6-speed automatic transmission /VE/ Lambda/New Gamma), Kia Motors, Hyundai Transys(8-speed automatic transmission), Valeo Kapec, Hyundai Kefico, Hyundai Wia, Mando, Central, Hanon Systems(Bearing bore gauge), TRW, Pyunghwa Automotive, Inzi Controls, Delphi, Austem, Namyang Nexmo, etc.

-

2011 ~ Present

Hyundai Motors(Nu/Kappa Engine), Kia Motors(Nu/New R), Hyundai Mission, Eco Mission, Valeo Kapec, Hyundai Wia(Kappa), Hyundai Transys, Hyundai Kefico, Hanon Systems, Austem, Mando, S&T Heavy Industry, Samsung Electronics, LG Innotek, LG Electronics, Kia Motors(Nu/New R), Hanmi Semiconductor, etc.a

Sales Records_Overseas

Export Countries: USA, Japan, China, Germany, India, Italy, Spain, Hungary, Poland, the Czech Republic, Vietnam, Thailand, Turkey, Mexico, Slovakia, Canada, Australia, Brazil, etc.

-

Japan

Toyota Motors, Double R&D, etc.

-

China

Beijing Hyundai Automobile, Beijing Hyundai Movis, Hyundai Wia Rizhao plant, Hyundai Transys Rizhao plant, Changsha/Jining Geely Auto, Kunshan Posco-Austem, Harbin Dongan Auto Engine, Qingshan Changan Automobile, Suzhou Samsung Electronics, Shaeffler, Sanhua, etc.

-

North America, EU

Hyundai Motors, Kia Motors, Germany Bosch, USA Global Tooling, REI, etc.

-

Vietnam, Thailand

Kia Motors, Hyundai Kefico, Eureka Automation, etc.

-

India, Turkey

Hyundai Motors, Kia Motors, Hyundai Wia, Aditya Engineering, PressKraft Engineering, Turkey Bosch, etc.

-

Brazil

Hyundai Motors